Giant squid tubes processing Steps

The processing of Peruvian giant squid tubes (usually referring to the squid mantle/body tube) is a relatively mature and industrialized process, aiming to produce frozen squid tubes that are safe, hygienic, meet international standards, and suit the needs of different markets. Here is its typical processing procedure:

Fishing and Transportation:

Fishing: Large purse seiners or longline boats are mainly used for fishing in the rich waters of the Peruvian Current (Humboldt Current). Giant Squid (primarily Dosidicus gigas) is the main target.

On-board processing: After capture, the giant squid is quickly sorted, cleaned (to remove impurities and seawater), and immediately quick-frozen. This is the most critical step, directly determining the quality of the final squid product.

Methods: Plate freezers or blast freezing tunnels are usually used.

Requirements: The core temperature of the giant squid should be lowered to -18°C or lower (such as -30°C to -40°C) within the shortest possible time (usually a few hours) to form small and uniform ice crystals, which can maximize the integrity of the cell structure and reduce juice loss and texture changes after thawing. The frozen giant squid after flash freezing is called whole frozen or boat-frozen giant squid.

Transportation: The frozen giant squid is stored in on-board refrigerators or refrigerated warehouses (-18°C to -25°C) when transported back to the port, waiting for subsequent processing or directly exported as squid raw materials.

Squid Raw Material Receiving and Thawing:

Receiving inspection: When receiving frozen giant squid raw materials, processing plants will conduct strict inspections, including temperature checks (to ensure the whole cold chain), sensory checks (appearance, smell), specification sampling, and possible safety index sampling (such as heavy metals, microorganisms).

Thawing: Frozen giant squid is thawed according to the production plan. Common methods include:

Running water thawing: Thawing in clean, low-temperature (usually <15°C) flowing water, which is fast, but the water temperature and time need to be controlled to prevent excessive water absorption or bacterial growth.

Refrigerator thawing: Slow thawing in a low-temperature (0-4°C) refrigerator, which takes a longer time but results in better quality with less juice loss.

Thawing requirements: The core temperature only needs to reach 0-4°C to avoid texture softening and microbial growth caused by over-thawing. The thawing process must be carried out under hygienic conditions.

Squid Pretreatment:

Cleaning: After thawing, the giant squid is first cleaned through multiple runs of flowing water to remove surface mucus, residual visceral fragments, and impurities.

Removal of head and viscera:

Manual or semi-automatic mechanical operation.

Workers hold the giant squid's body tube (mantle) with one hand and pull out the head together with the viscera with the other hand. At this time, the giant squid tube (mantle) is separated from the head, viscera, fins, and cartilage (pen/cuttlebone).

Removal of cartilage: Take out the transparent horny cartilage (pen) from the inside of the giant squid tube.

Skin removal/peeling: Depending on customer requirements, it may be necessary to remove the purple or brown outer skin of the squid tube. This can be done by:

Mechanical peeling machines: Using friction and water spraying for removal.

Chemical-assisted peeling: Sometimes, a short soak in a weak alkaline solution is used to soften the skin, which is then removed mechanically (strict control is required).

Manual peeling: For high-quality products or specific parts.

Removal of fins: If not removed before, the triangular fins attached to the open end of the mantle need to be cut or torn off.

Cleaning and trimming: Thoroughly clean the inside and outside of the giant squid tube again to remove residual skin debris, visceral fragments, etc. Trim the edges to remove damaged or irregular parts.

Grading and Sorting:

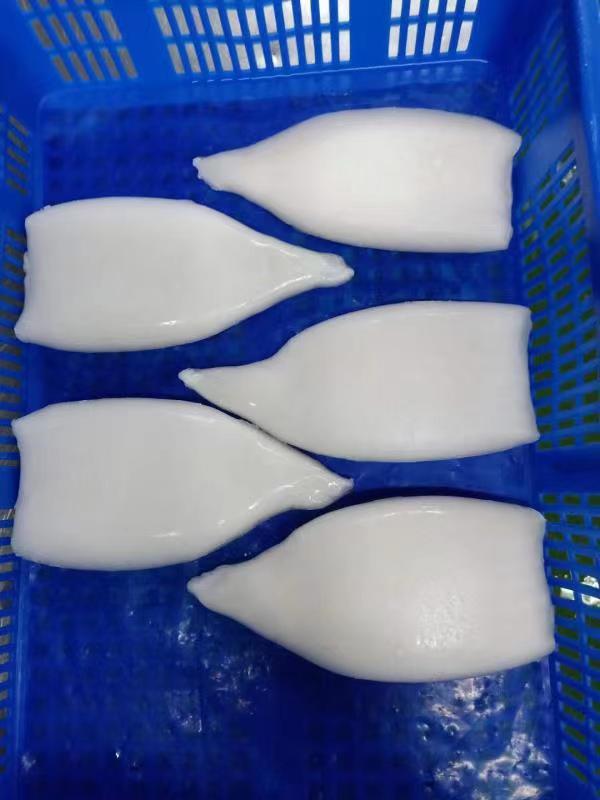

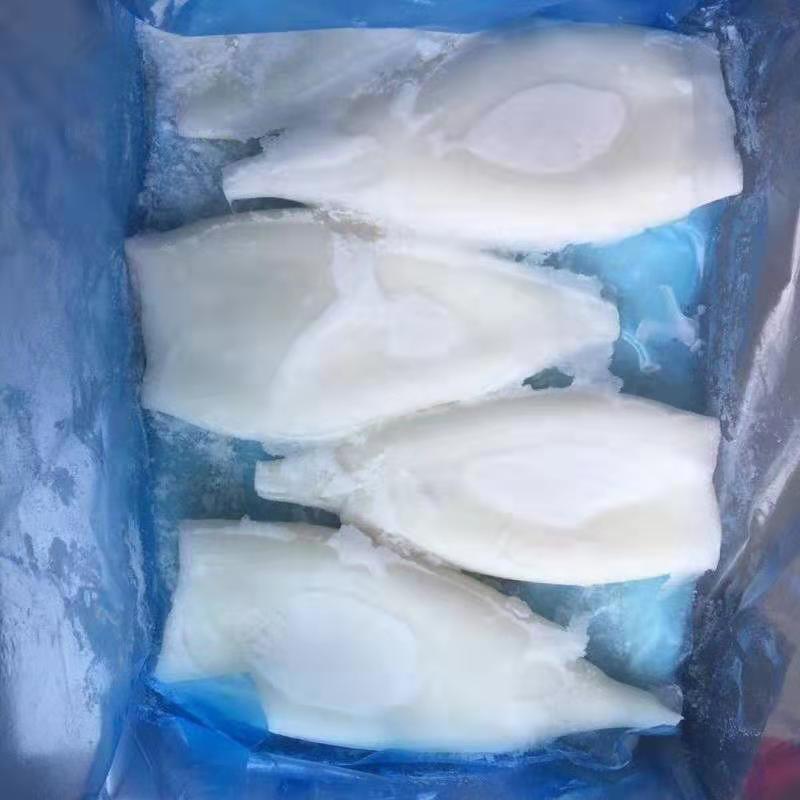

Strict grading and sorting are carried out according to tubes size/weight (such as weight per piece squid tube: 50-100g, 100-200g, 200-300g, 300g+, etc.) and quality (integrity of appearance, uniformity of color, presence of damage, black spots, etc.).

Grading standards are implemented in accordance with customer contract requirements or internal factory standards.

Cleaning and Disinfection:

The graded squid tubes are cleaned again in a flowing water tank for the final time.

They may be briefly soaked in a disinfection tank (such as ice water containing a certain concentration of sodium hypochlorite or other food-grade disinfectants) for disinfection to reduce microbial load (strict control of concentration and time is required, and residual disinfectants must be thoroughly rinsed off).

Water Control/Draining:

The cleaned and disinfected squid tubes need to have excess surface water effectively removed to prevent freezing agglomeration and excessive ice crystal formation. Common methods include:

Vibrating draining screens/conveyors: Removing most of the water through vibration.

Centrifugal dryers: More efficiently removing surface water.

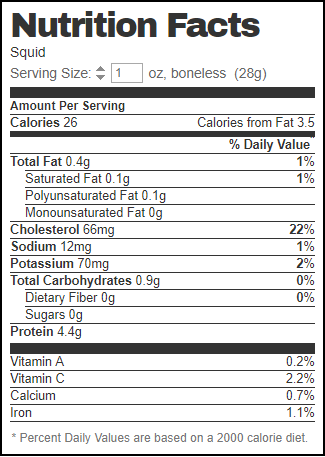

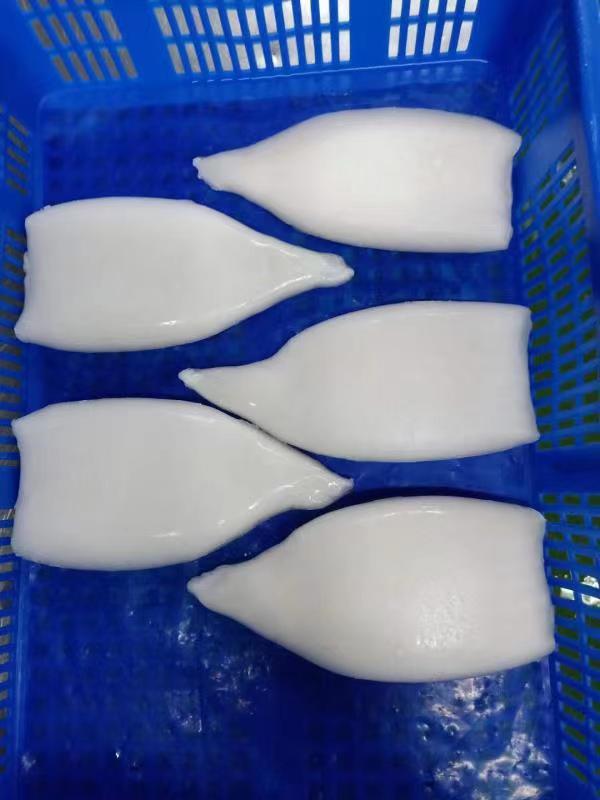

Plating/Loading:

The drained squid tubes are plated according to specifications and customer requirements:

Individual quick freezing: Place each squid tube flat on a metal tray or conveyor belt to ensure no adhesion. This is the most common method, and the product is called individually quick-frozen squid tubes, IQF squid tubes.

Block freezing: Arrange multiple squid tubes neatly in a plastic mold, add water or not, and freeze into blocks (this method is now less used for mantles and more common for squid rings or minced meat).

Quick Freezing:

The plated squid tubes are immediately sent to a freezing tunnel or spiral freezer.

They are quickly frozen under strong cold air (-30°C to -40°C or lower) to make the core temperature of the product quickly reach below -18°C. Quick freezing is also a key link to ensure product quality, especially in terms of texture and juice retention.

Unloading/Packaging:

Unloading: After freezing, the individually quick-frozen squid tubes are knocked off the trays.

Weighing: Weigh according to the packaging specifications.

Inner packaging: Usually packed into plastic film bags (such as PE bags) that meet food hygiene standards. Sometimes vacuum packaging or nitrogen-filled packaging is used to extend the shelf life and prevent freezer burn.

Outer packaging: The inner-packaged products are put into cartons or paper boxes, with product information labels (product name, specifications, batch number, production date, shelf life, factory registration number, etc.) attached. The cartons must meet strength requirements and be suitable for long-distance transportation.

Metal Detection:

The packaged finished products must pass through a metal detector to ensure no metal foreign objects are mixed in the products.

Cold Storage:

The qualified finished cartons are immediately transferred to a low-temperature cold storage at -18°C to -25°C for storage, waiting for shipment. A stable low temperature (cold chain) must be maintained throughout the storage and transportation process.

Quality control points run through the entire process:

HACCP system: Processing plants must establish and implement a Hazard Analysis and Critical Control Points system to identify and control biological, chemical, and physical hazards.

GMP/SSOP: Strictly abide by Good Manufacturing Practices and Sanitary Standard Operating Procedures to ensure the hygiene of the processing environment, cleanliness of equipment, and personal hygiene of workers.

Temperature monitoring: Temperature records of the entire cold chain from raw materials to finished products are crucial.

Sensory inspection: Inspections of appearance, smell, and texture are conducted at multiple stages.

Microbial and physical-chemical testing: Regular sampling and testing of raw materials, semi-finished products, finished products, processing water, and the environment are carried out to ensure compliance with safety and hygiene standards (such as total bacterial count, coliforms, Salmonella, heavy metals, drug residues, etc.).

Traceability: A complete recording system to ensure the traceability of products from raw materials to finished products.

Final product forms:

The most common finished form of Peruvian giant squid tubes is individually quick-frozen squid tubes, and some are peeled or unpeeled. They are widely used in the catering industry (teppanyaki, barbecue, stir-frying, hot pot, frying) and the food processing industry (making squid rings, squid flowers, squid skewers, squid balls, etc.).

In general, the processing of Peruvian giant squid tubes is a combination of efficient fishing, rapid on-board freezing for preservation, and modern, standardized onshore processing procedures that focus on hygiene and safety. Its core lies in quick freezing and the whole cold chain to maximize the freshness and texture of the products.

China giant squid tubes supplier, China giant squid tubes producer, China giant squid tubes factory, China seafoods supplier, China giant squid tubes exporter, China giant squid tubes manufacturer, giant squid rings, giant squid flowers, giant squid tentacles, giant squid fillets, seafoods